Hazard analysis critical control point (HACCP) is an internationally recognized food safety system that is employed in the production line of food and food products in food processing industries to ensure food safety, food hygiene and good food quality. It is a quality assurance technique or system that is used especially in food processing and production industries to evaluate the possible hazards or risks that are eminent in the entire manufacturing process of food and food products so that sustainable measures could be put in place to contain and minimize them.

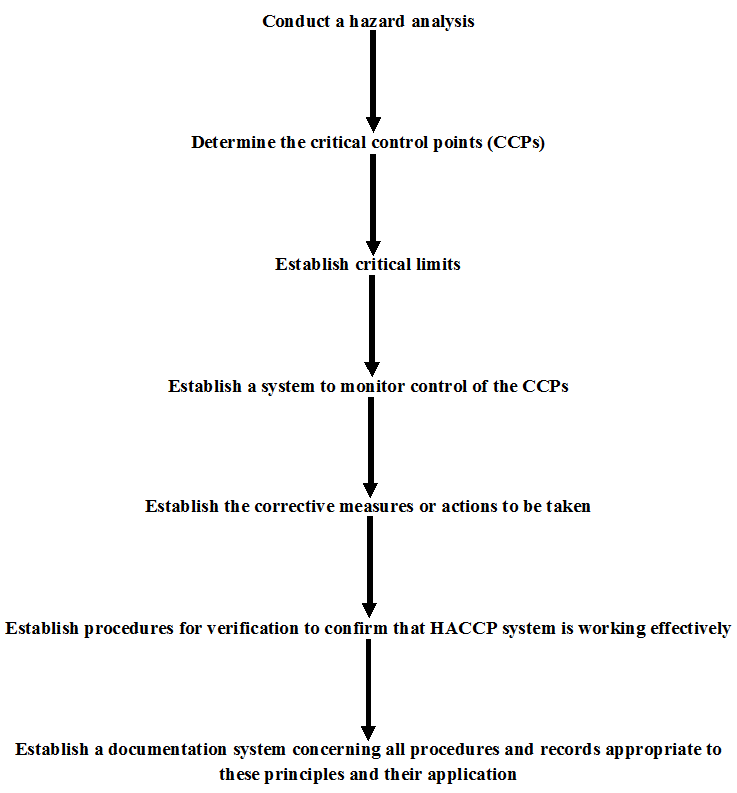

HACCP is mainly made up of seven (7) steps or principles that set the foundation for ensuring hygiene conditions and requirements by food companies in the production lines of food (Figure 1). Amongst other factors, the HACCP technique identifies risks in food production, evaluates these risks and hazards and controls all the possible hazards that generally affect food safety and hygiene.

Food processing companies ensures that all the principles of HACCP are implemented at every stage of their production to eliminate all possible hazards in their final end products. Though the safety and hygiene of foods rest largely on the government who should monitor these industries and ensure that their operations are within the ambit of the law and that their manufactured goods portend no health risk to the final consumer; it is also the responsibilities of the industries themselves to ensure that their products are safe and hygienically fit for the end-users.

Food industries who take the safety and hygiene of their products serious see it as a responsibility to imbibe the principles of the HACCP and other good manufacturing practices (GMPs) in order to assuage or minimize all possible hazards in their productions. Food has to be hygienically safe in order to be acceptable by end-users or consumers; and it is expected that they do not cause any health risk or harm when consumed.

In HACCP, the personnel’s involved in the production, testing techniques of end products, quality control of the production process and the maintenance of a hygienic production environment are all covered. The HACCP technique should be a key part of the GMPs of food industries because it provides the basic operating and environmental conditions necessary for the production of hygienic, suitable and safe food.

Most of the microbiological tests carried out in food production plants are mainly designed to detect the presence or contamination of food by some non-specific organisms; and majority of these tests look out for gas production amongst other factors that are key indicators for the presence of contaminating microorganisms in the food under test.

The microbiological tests used in food industries detect the metabolic by-products of microbes which are key indicators that a contaminating organism is present in the food. For the detection of Gram negative bacteria in food, some specific tests such as the Limulus Amoebocyte Lysate (LAL) test which detect the presence of lipopolysaccharides (LPS) and other exotoxins produced by Gram negative organisms can also be applied.

In addition to this, PCR technology could also be employed to detect the specific microbes present in food samples; and this is feasible especially when the microorganism’s specific primers are readily available. The hazard analysis critical control point (HACCP) is a detailed assessment of the production process and control of potential hazards at certain critical points in the production line of a given product (e.g. food).

The “hazard” in this case generally refers to factors which would adversely affect the entire process as well as the end product if not avoided at an early stage. This is only possible after carrying out a detailed assessment of known hazards of the production process including those associated with the personnel and raw materials used for the production. After this, the identification of critical control points (CCPs) as shown in Figure 1 is another step to be taken in the production process.

The CCPs generally refers to specific stages of the production process at which interventions can be taken or implemented in order to minimize or avoid completely the negative effects of particular risks. At the CCPs, the production process is routinely and carefully monitored; and this is mainly aimed at ensuring that the entire process proceeds in such a manner that will avoid contamination and ensure the production of quality products aside other important factors.

Assessing the level of microbial contamination of the process is an important microbiological monitoring that can be carried out at CCPs. In such scenarios, the presence of specific microorganisms known to cause contamination of the process are assayed for and reported. And it is expected that the results of such tests are obtained on time so that measures could be promptly taken to correct the anomaly in the production process.

References

Bushell M.E (1998). Application of the principles of industrial microbiology to biotechnology (ed. Wiseman, A.) Chapman and Hall, New York.

Byong H. Lee (2015). Fundamentals of Food Biotechnology. Second edition. Wiley-Blackwell, New Jersey, United States.

Clark D.P and Pazdernik N (2010). Biotechnology. First edition. Elsevier Science and Technology Books, Amsterdam, Netherlands.

Farida A.A (2012). Dairy Microbiology. First edition. Random Publications. New Delhi, India.

Frazier W.C, Westhoff D.C and Vanitha N.M (2014). Food Microbiology. Fifth edition. McGraw-Hill Education (India) Private Limited, New Delhi, India.

Guidebook for the preparation of HACCP plans (1999). Washington, DC, United States Department of Agriculture Food Safety and Inspection Service. Accessed on 20th February, 2015 from: http://www.fsis.usda.gov

Hayes P.R, Forsythe S.J (1999). Food Hygiene, Microbiology and HACCP. 3rd edition. Elsevier Science, London.

Hussaini Anthony Makun (2013). Mycotoxin and food safety in developing countries. InTech Publishers, Rijeka, Croatia. Pp. 77-100.

Jay J.M (2005). Modern Food Microbiology. Fourth edition. Chapman and Hall Inc, New York, USA.

Lightfoot N.F and Maier E.A (1998). Microbiological Analysis of Food and Water. Guidelines for Quality Assurance. Elsevier, Amsterdam.

Nduka Okafor (2007). Modern industrial microbiology and biotechnology. First edition. Science Publishers, New Hampshire, USA. Roberts D and Greenwood M (2003). Practical Food Microbiology. Third edition. Blackwell publishing Inc, USA.

Discover more from #1 Microbiology Resource Hub

Subscribe to get the latest posts to your email.