Beer is an alcoholic beverage that is produced industrially by the microbial fermentation of wort (sugary solutions obtained by the dissolution of malted cereal grains). The process by which wort is converted into alcohol by microbes such as yeasts is known as brewing. The art of beer production (i.e. brewing) is an ancient practice known to mankind over many thousand years ago. The major raw materials for beer production in the industry include water, hops, malt, yeasts, and adjuncts (which are usually added during beer production to increase and improve the alcoholic content of the beer).

Adjuvants also act as other carbohydrate sources for beer production; and they possess properties that beneficially supplement the principal raw material (e.g. barley) used for the brewing process. They act as cheaper sources of extract and starch to the brewing process; and they also increase the production of beer especially in cases where there is limited brew house capacity.

Nevertheless, adjuvants are not always used by all brewing industries because of some demerits that they bring along. Adjuvants may cause unusual or unwanted flavour development in the beer; and complete saccharification is usually difficult with adjuvants. There is also the issue of slower filtration of the mash when adjuvants are used for brewing.

Hops are aromatic plants that give beer its flavour and bitterness; and they are naturally sourced from the female flower plant known as Humulus lupulos. H. lupuloscontribute to the formation of a good froth (foam) and it also protects the beer against any possible microbial contamination. Hops contain or produce both resins and essential oils.

The resins provide the precursors that impart bitterness to the beer while the essential (volatile) oils provide the aroma associated with the plant, and which also imparts on the flavour of the beer. Since natural water may not be always available for brewing process, it is vital to treat water for brewing processes because the pH, mineral and ionic content of the water may impact or affect the beer being brewed.

Water for brewing processes can be treated through ion exchange, de-carbonation and by the addition of acid or base to regulate the pH of the water. Beer is produced in the industry through alcoholic fermentation.

Alcoholic fermentation is carried out by yeasts such as Saccharomyces cerevisiae and bacteria such as Zymomonas species; and it is metabolic process in which microbes degrade their substrates to produce ethanol or alcohol. Alcoholic beverages including beers, champagnes, wines and distilled spirits are produced through alcoholic fermentation processes. Alcoholic fermentation extends the shelf-life and/or keeping quality of food/beverage products; and it also improves on the physical features of the end-products.

Alcoholic beverages enhance the flavour of the end-product; and it is mainly used to change the parent foodstuff (substrate) to a new and improved food product. These beverages are mainly manufactured from locally available fermentable substrates which are sugar based. These sugar based materials or substrates from which alcoholic beverages are manufactured from include rice, sorghum, wheat, millet, maize and barley.

It is also noteworthy that the fruit juices of some plants, and plant saps can also act as substrates for the production of alcoholic beverages especially wine. The microbes involved in these alcoholic fermentations are mainly strains of S. cerevisiae – that on their own cannot directly ferment starch without a prior enzymatic hydrolysis of the substrate (starch) to simple sugars (e.g. glucose). As aforementioned, rice, sorghum, wheat, millet, maize and barley are the major source of carbohydrate substrates for beer production.

Barley is extensively used for beer production due to its unique properties. Barley contains high amount of amylase enzyme (for starch hydrolysis); and this gives it a good enzymatic composition. Barley yields the desired fermentable extracts, and its thick husks make the brewing process (especially malting and filtration) much easier than when other cereal grains are used. Barley has a gelatinization temperature (52-29oC) which makes the solubilization and hydrolysis of its starch possible in one operation. The thick husks of barley prevent the grain from possible fungal infection especially during storage. These features of barley make it a benchmark against which other cereal grains can be compared.

The most important ingredient in beer production is a microorganism, yeast in the Kingdom Fungi. The type of yeast used in beer production impacts hugely on the flavor and texture of the drink depending on the type of beer being brewed. In beer production, the grains are germinated and their enzymes are activated to produce malt. The grain is usually mixed with water and the mixture is then transferred to a mash in a vessel.

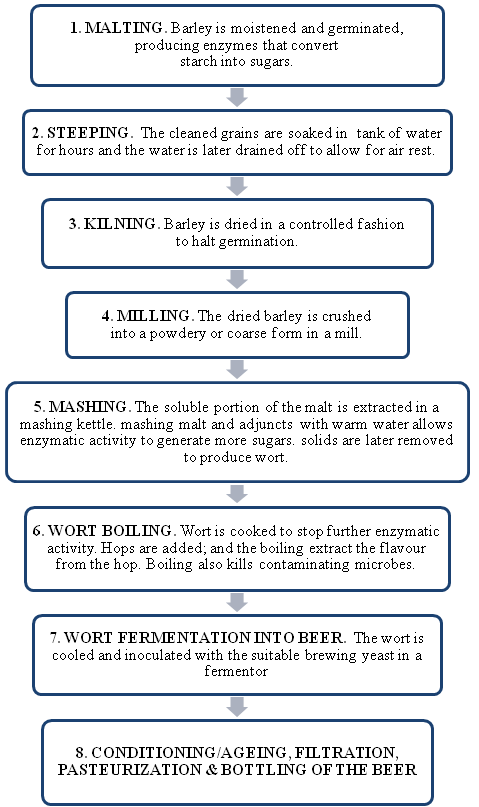

It is later heated with hops which help to inhibit spoilage organisms and also provide flavour as well as assist in the clarification of the wort. After this, the wort is pitched (i.e. inoculated) with the desired yeasts (e.g. S. carlsbergensis and S. cerevisiae) depending on the type of beer to be produced. Malting, steeping, kilning, milling, mashing, boiling of the wort, fermentation, conditioning/ageing, pasteurization and bottling are some of the processes involved in beer production (Figure 1).

References

Bader F.G (1992). Evolution in fermentation facility design from antibiotics to recombinant proteins in Harnessing Biotechnology for the 21st century (eds. Ladisch, M.R. and Bose, A.) American Chemical Society, Washington DC. Pp. 228–231.

Nduka Okafor (2007). Modern industrial microbiology and biotechnology. First edition. Science Publishers, New Hampshire, USA.

Das H.K (2008). Textbook of Biotechnology. Third edition. Wiley-India ltd., New Delhi, India.

Latha C.D.S and Rao D.B (2007). Microbial Biotechnology. First edition. Discovery Publishing House (DPH), Darya Ganj, New Delhi, India.

Nester E.W, Anderson D.G, Roberts C.E and Nester M.T (2009). Microbiology: A Human Perspective. Sixth edition. McGraw-Hill Companies, Inc, New York, USA.

Steele D.B and Stowers M.D (1991). Techniques for the Selection of Industrially Important Microorganisms. Annual Review of Microbiology, 45:89-106.

Pelczar M.J Jr, Chan E.C.S, Krieg N.R (1993). Microbiology: Concepts and Applications. McGraw-Hill, USA.

Prescott L.M., Harley J.P and Klein D.A (2005). Microbiology. 6th ed. McGraw Hill Publishers, USA.

Steele D.B and Stowers M.D (1991). Techniques for the Selection of Industrially Important Microorganisms. Annual Review of Microbiology, 45:89-106.

Summers W.C (2000). History of microbiology. In Encyclopedia of microbiology, vol. 2, J. Lederberg, editor, 677–97. San Diego: Academic Press.

Talaro, Kathleen P (2005). Foundations in Microbiology. 5th edition. McGraw-Hill Companies Inc., New York, USA.

Thakur I.S (2010). Industrial Biotechnology: Problems and Remedies. First edition. I.K. International Pvt. Ltd. New Delhi, India.

Discover more from #1 Microbiology Resource Hub

Subscribe to get the latest posts to your email.