Sterilization is defined as any process by which objects, materials or an environment may be rendered sterile (i.e. completely free from all forms of life). Sterilization is the process by which all living cells, viable spores, viruses and viroids are either destroyed or removed from an object or habitat. It is essential for all fermentation processes; and sterilization helps to ensure the yield of desired products free from contaminating microorganisms. Sterility is of utmost importance in any fermentation process; and it must form an integral part of every industrial fermentation process in order to avoid the growth of unwanted contaminants and in achieving maximal yield of a byproduct by the use of fermentation process using known cultures as inoculum.

All the components of fermentation processes including the fermenter and fermentation media need to be sterilized so as to remove every form of contamination prior to or during the fermentation process. The fermentation vessel and other accessory equipment must be sterilized to ensure pristine (pure) conditions and virtually no contamination. Different techniques of sterilization are available based on the properties of the component being sterilized.

The most commonly used sterilization techniques include moist heat (steam) sterilization, dry heat sterilization, incineration, and boiling; sterilization by chemicals; sterilization by filtration; and sterilization by the use of radiation. The most common means of achieving sterilization in industrial production processes is sterilization by moist heat (steam).

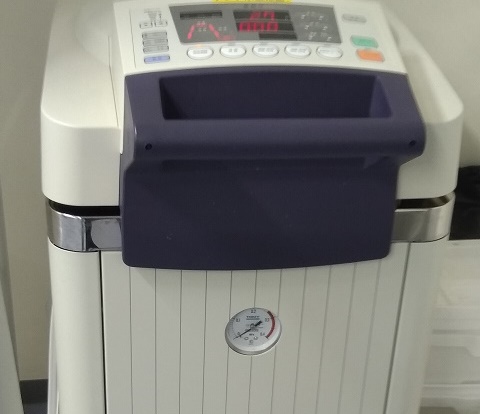

Most of the fermentation components like culture medium, small fermenters and glassware’s are sterilized by moist heat sterilization technique. This method of sterilization is best for heat labile materials.The sterilization of fermenters is also made possible using moist heat (steam). The fermenter and the accessory pipe lines attached to the fermenter are sterilized by the use of hot steam which is passed throughout the heating coils within the fermenter.

Dry heat (hot) air sterilization is used to sterilize by oxidizing the cellular components of the microorganisms. Dry heat is less effective than moist heat sterilization. In dry heat sterilization, the materials to be sterilized are sterilized in an oven at high temperatures of about 160°-180oC for about 1 hour to attain complete sterilization. Hot air ovens are used to sterilize equipment in the fermentation process. The equipment to be sterilized should withstand high temperatures. Glass Petri dishes, borosilicate or Pyrex glass equipments, measuring cylinders and other glassware’s are usually sterilized using dry heat. The inner chamber of the oven is made of heat resistant stainless steel and has a fan to circulate the hot air evenly throughout the chamber to ensure proper heat transfer.

Incineration is another means of achieving sterilization; and it is usually used to sterilize waste materials before their disposal in the environment. In incineration (burning) processes, the objects to be sterilized are directly exposed to flames to kill all microorganisms. This is the most effective method of sterilization but suitable only for heat stable components like metal and some glass objects such as inoculation loops, needles and heat stable glassware.

Boiling is a sterilization method used to sterilize liquids by boiling them at 100°C for 30 minutes which kills most of the microorganism’s especially vegetative cells. Boiling is not effective for the killing of spore-forming microbes. Sterilization can also be achieved by the use of chemicals such as ethylene oxide gas, formaldehyde gas, chlorine, ethyl alcohols, hydrogen peroxide and formaldehyde. These gases or chemicals are used to achieve chemical sterilization; and chemical methods of sterilization are used to sterilize materialswhich cannot withstand the high temperatures of heat (steam) sterilization.

Filtration technique is another type of sterilization which is used in the industry.Sterilization by filtrationmethod is used to sterilize liquids or materials which are heat sensitive and cannot withstand moist or dry heat. Such heat sensitive materials are passed through membrane filters of varying sizes – which hold back bacteria and some microbes. Sterilization by radiation uses ionizing radiations and ultraviolet (UV) light to perform sterilization in the industry. This method can be used to sterilize materials such as filters, gases, and other heat sensitive components in the industry.

References

Bader F.G (1992). Evolution in fermentation facility design from antibiotics to recombinant proteins in Harnessing Biotechnology for the 21st century (eds. Ladisch, M.R. and Bose, A.) American Chemical Society, Washington DC. Pp. 228–231.

Nduka Okafor (2007). Modern industrial microbiology and biotechnology. First edition. Science Publishers, New Hampshire, USA.

Das H.K (2008). Textbook of Biotechnology. Third edition. Wiley-India ltd., New Delhi, India.

Latha C.D.S and Rao D.B (2007). Microbial Biotechnology. First edition. Discovery Publishing House (DPH), Darya Ganj, New Delhi, India.

Nester E.W, Anderson D.G, Roberts C.E and Nester M.T (2009). Microbiology: A Human Perspective. Sixth edition. McGraw-Hill Companies, Inc, New York, USA.

Steele D.B and Stowers M.D (1991). Techniques for the Selection of Industrially Important Microorganisms. Annual Review of Microbiology, 45:89-106.

Pelczar M.J Jr, Chan E.C.S, Krieg N.R (1993). Microbiology: Concepts and Applications. McGraw-Hill, USA.

Prescott L.M., Harley J.P and Klein D.A (2005). Microbiology. 6th ed. McGraw Hill Publishers, USA.

Steele D.B and Stowers M.D (1991). Techniques for the Selection of Industrially Important Microorganisms. Annual Review of Microbiology, 45:89-106.

Summers W.C (2000). History of microbiology. In Encyclopedia of microbiology, vol. 2, J. Lederberg, editor, 677–97. San Diego: Academic Press.

Talaro, Kathleen P (2005). Foundations in Microbiology. 5th edition. McGraw-Hill Companies Inc., New York, USA.

Thakur I.S (2010). Industrial Biotechnology: Problems and Remedies. First edition. I.K. International Pvt. Ltd. New Delhi, India.

Discover more from #1 Microbiology Resource Hub

Subscribe to get the latest posts to your email.