Continuous fermentation is defined as the fermentation process in which sterile growth nutrients are added continuously to the fermentation vessel and an equal amount of converted nutrient solution (end-product) with microorganisms is simultaneously harvested in the process. It is also known as an open culture system – since it allows nutrients to be continuously added during the fermentation process.

In batch cultures, nutrients are not renewed and so growth remains exponential for only a few generations. But this is not the case in continuous fermentations – in which a steady state or balance microbial growth can be obtained.

Microbial population can be maintained in a state of exponential growth for a long time by using a continuous fermentation system or culture. The exponential growth of the culture is continuous until a time when the fermentation vessel is completely filled with the fermentation media.

The balanced microbial growth obtainable in continuous culture systems is maintained by supplying growth medium continuously; and the growth medium is designed or compounded in such a way that microbial growth is restricted by substrate and not by toxin buildup. And this allows an exponential growth of the organism by addition of new fresh medium.

The rate of addition of fresh growth medium determines the rate of growth because the fresh medium always contains a limiting amount of an essential nutrient. The chemostat and turbidostat are typical examples of continuous fermentation systems used for the continuous culture of microbes in the laboratory.

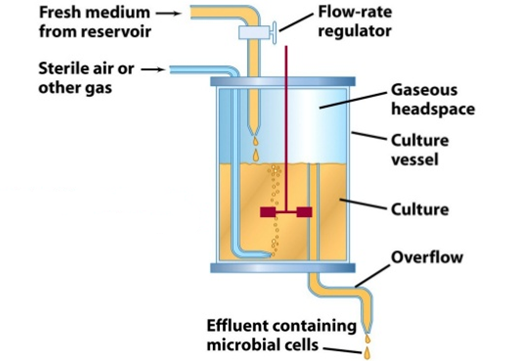

Chemostat is a continuous fermentation apparatus that feeds nutrient medium into the culture vessel at the same rate as the medium containing the microorganisms is removed (Figure 1). The medium in a chemostat contains one essential growth nutrient (e.g. amino acid) in a limiting amount; and because a sub-maximal amount of the essential growth nutrient is used at any given time, a constant population of the microbial cell is maintained in a constant volume.

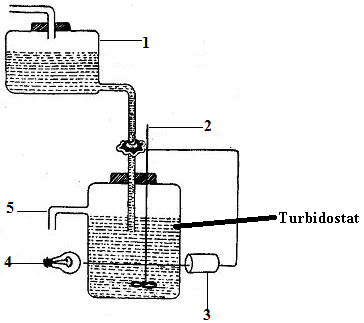

Turbidostat is a continuous fermentation system that is fitted with a photocell that adjusts and regulates the flow of nutrient medium through the culture vessel in order to maintain a constant cell density or turbidity (Figure 2). Unlike the chemostat where the nutrient is limited, the nutrients are present in excess amounts in the turbidostat; and the cell density (turbidity of the medium) is monitored by the photocell device – which translates any change in turbidity to a mechanism that automatically reduces or increases the rate of the nutrient inflow and broth outflow as deemed necessary.

The turbidostat system consists of an optical-sensing device (the photo cell) which measures the absorbance of the culture density (turbidity) in the growth vessel. Changes in turbidity retard (or increase) passage of light (from the photo cell) through the culture; and these changes activate mechanisms that control the flow of nutrients in the turbidostat system as well as the flow of waste materials out of the main culture vessel. Chemostat and turbidostats are the two types of continuous fermentation vessels used to ensure steady states of microbial cells during a fermentation process.

In the chemostat, the steady state is ensured by adjusting the concentration of one substrate; and this controls the cell growth. Cell growth is kept constant in the turbidostat by using turbidity to monitor the biomass concentration and the rate of inflow of nutrients is also adjusted in the process. A constant chemical environment is maintained in a chemostat while a constant cell concentration is maintained in a turbidostat.

The parameters that initiate a stationary phase of growth in a fermentation vessel include nutrient depletion, accumulation of toxic substances and accumulation of excess cells in the vessels. These parameters are usually out ruled in the open system of culture since nutrients are continuously added to the system to maintain a steady microbial growth over a long period of time. Generally, continuous fermentation involves addition of substrates in an unbroken stream and the withdrawal of fermentation medium in the same manner. Continuous fermentation has advantages and disadvantages.

MERITS OF CONTINUOUS FERMENTATION

- Continuous systems allow microbial growth to be regulated and maintained over a long period of time.

- It provides opportunity for studying the metabolic processes of organisms.

- It can be used to obtain a steady-state of microbial growth.

- Continuous culture results in higher productivity per unit volume. And this is because time consuming tasks such as sterilization, filling, cleaning and emptying of the vessel are out ruled.

- It results in the production of high quality products because of the steady-state of continuous culture.

DEMERITS OF CONTINUOUS FERMENTATION

- The major drawback in the use of continuous fermentation is in the nature of its operation. If the fermentation step in a process is operated continuously, it is most desirable to have all other steps of preparation and product recovery also in continuous operation. And in such a continuous process, a failure in one step will force a complete shutdown of the entire process.

- Continuous culture systems are prone to contamination because it is operated over a long period of time.

- It is not reliable in maintaining the growth of filamentous organisms such as fungi because of the viscosity and heterogeneous nature of the mixture in the vessel.

- The original product strain could be lost over time during the fermentation process; and this usually occurs when a faster growing strain overtakes it.

- Steady-state of microbial growth could be prevented in continuous cultures due to wall growth and cell aggregation in the fermentation vessel.

SEMI-CONTINUOUS FERMENTATION

Semi-continuous fermentation is defined as the fermentation process in which the substrate is added and the product removed at intervals. It combines some of the features of batch and continuous fermentation. In semi-continuous cultures, a fixed volume of the fermented medium is usually taken out from the fermentation vessel, and the same volume of nutrients is simultaneously added to the fermenter – in order to keep the volume of the fermentation medium at the same level as well as replenish the depleted nutrients for microbial growth. Semi-continuous fermentation process can be used to maintain the microorganisms in the same phase of growth over some period of time.

References

Bader F.G (1992). Evolution in fermentation facility design from antibiotics to recombinant proteins in Harnessing Biotechnology for the 21st century (eds. Ladisch, M.R. and Bose, A.) American Chemical Society, Washington DC. Pp. 228–231.

Nduka Okafor (2007). Modern industrial microbiology and biotechnology. First edition. Science Publishers, New Hampshire, USA.

Das H.K (2008). Textbook of Biotechnology. Third edition. Wiley-India ltd., New Delhi, India.

Latha C.D.S and Rao D.B (2007). Microbial Biotechnology. First edition. Discovery Publishing House (DPH), Darya Ganj, New Delhi, India.

Nester E.W, Anderson D.G, Roberts C.E and Nester M.T (2009). Microbiology: A Human Perspective. Sixth edition. McGraw-Hill Companies, Inc, New York, USA.

Steele D.B and Stowers M.D (1991). Techniques for the Selection of Industrially Important Microorganisms. Annual Review of Microbiology, 45:89-106.

Pelczar M.J Jr, Chan E.C.S, Krieg N.R (1993). Microbiology: Concepts and Applications. McGraw-Hill, USA.

Prescott L.M., Harley J.P and Klein D.A (2005). Microbiology. 6th ed. McGraw Hill Publishers, USA.

Steele D.B and Stowers M.D (1991). Techniques for the Selection of Industrially Important Microorganisms. Annual Review of Microbiology, 45:89-106.

Summers W.C (2000). History of microbiology. In Encyclopedia of microbiology, vol. 2, J. Lederberg, editor, 677–97. San Diego: Academic Press.

Talaro, Kathleen P (2005). Foundations in Microbiology. 5th edition. McGraw-Hill Companies Inc., New York, USA.

Thakur I.S (2010). Industrial Biotechnology: Problems and Remedies. First edition. I.K. International Pvt. Ltd. New Delhi, India.

Discover more from #1 Microbiology Resource Hub

Subscribe to get the latest posts to your email.