Quality Assurance (QA) is a structured, systematic, and documented framework designed to ensure that products and services consistently meet predefined standards of quality, safety, and performance. In regulated sectors such as pharmaceutical manufacturing, clinical diagnostics, biotechnology, and healthcare delivery, QA is not merely a procedural requirement, it is a governance mechanism that safeguards public health, regulatory compliance, and organizational credibility.

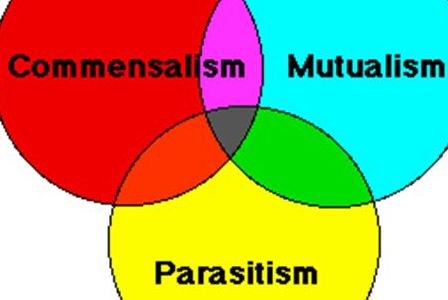

QA differs fundamentally from Quality Control (QC). While QC is reactive and product-oriented—focused on testing and verification of outputs – QA is proactive and process-oriented. It is concerned with designing, implementing, monitoring, and continuously improving systems to prevent defects before they occur. In other words, QC detects; QA prevents.

In healthcare and pharmaceutical environments, failure in QA can result in contaminated drugs, inaccurate laboratory results, therapeutic failure, antimicrobial resistance propagation, patient morbidity, and reputational damage. Therefore, a robust QA system must be embedded across all stages of production and service delivery from raw material procurement to post-market surveillance.

Definition of Quality Assurance

The World Health Organization defines quality assurance in laboratory medicine as the total process whereby the quality of laboratory reports can be guaranteed. This definition emphasizes that QA is comprehensive and spans the entire testing cycle.

In operational terms, QA ensures:

- The right result

- Delivered at the right time

- On the right specimen

- From the right patient

- Interpreted using the correct reference standards

- Reported to the right location or clinician

This framework is commonly referred to as the “Six Rights” of laboratory quality. It underscores that QA is not limited to analytical performance but encompasses the entire testing continuum – pre-analytical, analytical, and post-analytical phases.

QA vs QC vs In-Process Control

Quality Assurance (QA)

QA answers the question: Are we operating within a system that consistently produces safe, reliable, and compliant outcomes?

QA is system-based and preventive. It includes:

Development of Standard Operating Procedures (SOPs)

Standard Operating Procedures (SOPs) are controlled, written documents that describe in precise, step-by-step terms how routine operations must be performed. They are foundational to system-based QA because they reduce variability, enforce consistency, and ensure that tasks are executed according to validated methods. An effective SOP clearly defines scope, responsibilities, materials required, safety considerations, procedural steps, documentation requirements, and references.

SOPs must undergo formal review and approval before implementation and must be version-controlled to prevent the use of obsolete instructions. Periodic review ensures alignment with regulatory updates, process changes, or technological advancements. In regulated environments such as pharmaceutical manufacturing and clinical laboratories, SOPs also serve as auditable evidence that operations are standardized and reproducible. Without well-structured SOPs, preventive quality systems collapse into ad hoc practices, increasing the probability of deviation, non-conformity, and compliance failure.

Staff Training and Competency Assessment

Personnel competence is one of the most critical determinants of product and service quality. Even the most sophisticated systems fail if staff lack the technical knowledge, practical skill, or regulatory awareness required for proper execution. Within a preventive QA framework, training is not a one-time event but a structured, ongoing process that includes onboarding, role-specific instruction, refresher courses, and updates following procedural changes.

Competency assessment goes beyond attendance at training sessions. It involves direct observation, proficiency testing, written evaluations, and performance audits to verify that individuals can perform assigned tasks correctly and independently. Documentation of training and competency records is essential for regulatory inspections and accreditation purposes. In high-stakes settings such as sterile pharmaceutical production or microbiological diagnostics, inadequate training can lead to contamination, inaccurate results, or product recalls. Therefore, systematic competency management prevents errors before they occur rather than reacting after damage has been done.

Validation and Qualification of Equipment

Equipment used in pharmaceutical production and laboratory testing must consistently perform within predefined specifications. Validation and qualification provide documented evidence that instruments and systems operate as intended. Equipment qualification typically follows a structured sequence: Installation Qualification (IQ), which verifies proper installation; Operational Qualification (OQ), which confirms that the equipment operates according to manufacturer specifications; and Performance Qualification (PQ), which demonstrates consistent performance under real operating conditions.

Preventive QA requires not only initial qualification but also routine calibration, maintenance schedules, and requalification after repair or modification. Calibration must be traceable to certified reference standards to ensure measurement accuracy. Inaccurate or poorly maintained equipment can generate invalid data, compromise sterility, or produce substandard products. Therefore, systematic validation and qualification are proactive safeguards that protect data integrity and product quality before failures occur.

Documentation Systems

Documentation systems form the backbone of a preventive QA structure. In regulated industries, documentation provides objective evidence that processes were performed as required. This includes batch manufacturing records, laboratory worksheets, equipment logs, training files, deviation reports, and audit trails.

A robust documentation system enforces principles such as data integrity, traceability, and controlled access. Electronic documentation systems must incorporate user authentication, time-stamped audit trails, and secure data storage to prevent manipulation or loss. Version control ensures that only current, approved documents are in circulation. Proper documentation enables root cause analysis, regulatory review, and process improvement. Importantly, documentation shifts quality from reliance on memory or verbal communication to verifiable records. Without comprehensive documentation systems, preventive QA mechanisms cannot be demonstrated, evaluated, or improved.

Risk Assessment and Management

Risk assessment and management are central to modern preventive QA systems. Rather than treating all processes as equally critical, risk-based approaches identify areas where failure would have the greatest impact on product safety, efficacy, or regulatory compliance. Tools such as Failure Mode and Effects Analysis (FMEA), hazard analysis frameworks, and risk matrices help organizations prioritize control measures.

Risk management involves identifying potential failure points, evaluating their probability and severity, implementing mitigation strategies, and monitoring residual risk. This proactive approach allows organizations to allocate resources efficiently and prevent high-impact failures. In pharmaceutical manufacturing, for example, aseptic processes, sterilization cycles, and raw material quality may carry higher risk profiles than secondary packaging. By systematically analyzing and controlling risk, QA prevents deviations rather than reacting to them after adverse events or regulatory findings occur.

Internal Audits

Internal audits are structured, independent evaluations of whether processes comply with established SOPs, regulatory standards, and organizational policies. They function as an early detection system within preventive QA. Rather than waiting for external regulators to identify deficiencies, organizations conduct routine audits to uncover gaps, non-conformities, or areas for improvement.

Effective internal audits involve predefined audit criteria, trained auditors, documented findings, and management review. The objective is not punitive enforcement but systematic improvement. Audit outcomes should generate measurable action plans and follow-up verification. In pharmaceutical and clinical laboratory environments, internal audits frequently examine data integrity, training records, environmental monitoring logs, and deviation management processes. By identifying weaknesses before they escalate, internal audits preserve compliance status and maintain operational reliability.

Corrective and Preventive Actions (CAPA)

Corrective and Preventive Action (CAPA) systems provide a structured methodology for addressing non-conformities and preventing recurrence. Corrective actions focus on eliminating the root cause of identified problems, while preventive actions aim to avert potential issues before they materialize.

A robust CAPA system begins with deviation reporting and thorough root cause analysis, often using methodologies such as the “5 Whys” or fishbone (Ishikawa) diagrams. Once root causes are identified, targeted corrective measures are implemented, followed by verification of effectiveness. Preventive measures may involve revising SOPs, enhancing training, upgrading equipment, or modifying process controls.

CAPA systems ensure that problems are not treated superficially. Instead of merely correcting symptoms, they strengthen the overall quality system. In regulated industries, CAPA documentation is heavily scrutinized during inspections because it reflects organizational commitment to continuous improvement and systemic integrity.

Together, these seven elements illustrate why QA is fundamentally system-based and preventive. Each component – SOP development, personnel competency, equipment validation, documentation, risk management, internal auditing, and CAPA functions as a structural safeguard. When integrated effectively, they create a resilient quality management architecture that minimizes variability, anticipates failure, and protects patient safety and public health.

Quality Control (QC)

Quality Control (QC) is a product-oriented, detection-based component of a broader quality management system. Unlike Quality Assurance, which focuses on preventing defects through system design, QC concentrates on identifying defects or deviations in specific products or batches after production or during defined checkpoints. Its primary objective is to verify that a product conforms to predefined specifications, regulatory standards, and safety requirements before it is released for distribution or clinical use.

QC answers the question: Does this specific batch meet predefined specifications? QC is a component of QA, but it does not substitute for it.

QC is product-based and detective. It includes:

Testing of Finished Products

Testing of finished products involves systematic analytical evaluation of the final manufactured item to confirm that it meets predetermined specifications for identity, strength, purity, quality, and performance. This testing typically includes physical, chemical, and microbiological analyses, depending on the product type. For pharmaceutical dosage forms, parameters such as weight variation, dissolution rate, disintegration time, hardness, pH, viscosity, and assay potency may be assessed. The purpose is to detect manufacturing errors, contamination, formulation inconsistencies, or deviations from validated production parameters before market release. Finished product testing serves as the final verification checkpoint in the manufacturing lifecycle and provides documented evidence of compliance with regulatory and pharmacopoeial standards.

Microbiological Sterility Testing

Microbiological sterility testing is conducted to determine whether sterile pharmaceutical products such as injectables, ophthalmic solutions, or certain biologics are free from viable microorganisms. Because these products bypass the body’s natural defense barriers, even minimal contamination can result in severe infections, sepsis, or patient mortality. Sterility testing is typically performed using membrane filtration or direct inoculation methods under aseptic laboratory conditions. The test involves incubating samples in growth media for a specified duration to detect microbial proliferation. While sterility testing does not guarantee absolute sterility, it provides statistically significant assurance that the manufacturing process maintained aseptic integrity and complied with established sterility standards.

Chemical Purity Analysis

Chemical purity analysis evaluates whether a product contains only the intended active pharmaceutical ingredient (API) and acceptable levels of excipients, without harmful impurities or degradation products. This analysis commonly employs analytical techniques such as high-performance liquid chromatography (HPLC), gas chromatography (GC), ultraviolet-visible spectroscopy (UV-Vis), or mass spectrometry. Impurity profiling is critical because contaminants may originate from raw materials, synthesis byproducts, environmental exposure, or degradation during storage. Regulatory authorities impose strict impurity thresholds, particularly for toxic or genotoxic compounds. Chemical purity testing ensures that the product’s chemical composition aligns with validated specifications and that impurity levels remain within permissible safety limits.

Batch Release Testing

Batch release testing refers to the comprehensive evaluation of a specific production batch before it is approved for distribution. Each batch is assigned a unique identification number to ensure traceability throughout the supply chain. QC laboratories perform predefined tests on representative samples from the batch to confirm compliance with established quality attributes, including potency, uniformity, sterility (if applicable), labeling accuracy, and packaging integrity. Only after satisfactory review of analytical results and production documentation does the Quality Unit authorize release. Batch release testing ensures that variability between production cycles does not compromise product safety, efficacy, or regulatory compliance.

Stability Testing

Stability testing assesses how the quality attributes of a product change over time under the influence of environmental factors such as temperature, humidity, and light exposure. These studies are conducted under controlled storage conditions defined by international regulatory guidelines and are categorized into accelerated, intermediate, and long-term stability studies. Parameters such as potency, degradation products, physical appearance, pH, dissolution, and microbial integrity are periodically evaluated. The data generated establish the product’s shelf life, recommended storage conditions, and expiration date. Stability testing ensures that the product maintains its safety, effectiveness, and quality throughout its intended lifecycle, from manufacture to patient use.

Quality Control functions as the analytical verification arm of a quality management system. Through systematic testing and documentation, QC detects deviations, confirms conformity to specifications, and provides the scientific basis for product release decisions. Although QC is inherently reactive identifying defects after production it remains indispensable for safeguarding public health and maintaining regulatory compliance in pharmaceutical and clinical laboratory settings.

In-Process Control (IPC)

In-Process Control (IPC) refers to systematic testing and monitoring activities conducted during manufacturing to ensure that critical process parameters remain within validated limits and that product quality is maintained throughout production.

IPC ensures that processes remain within validated parameters while manufacturing is ongoing. It prevents deviation before it affects the final product.

In-process control involves testing and monitoring during production. Examples include:

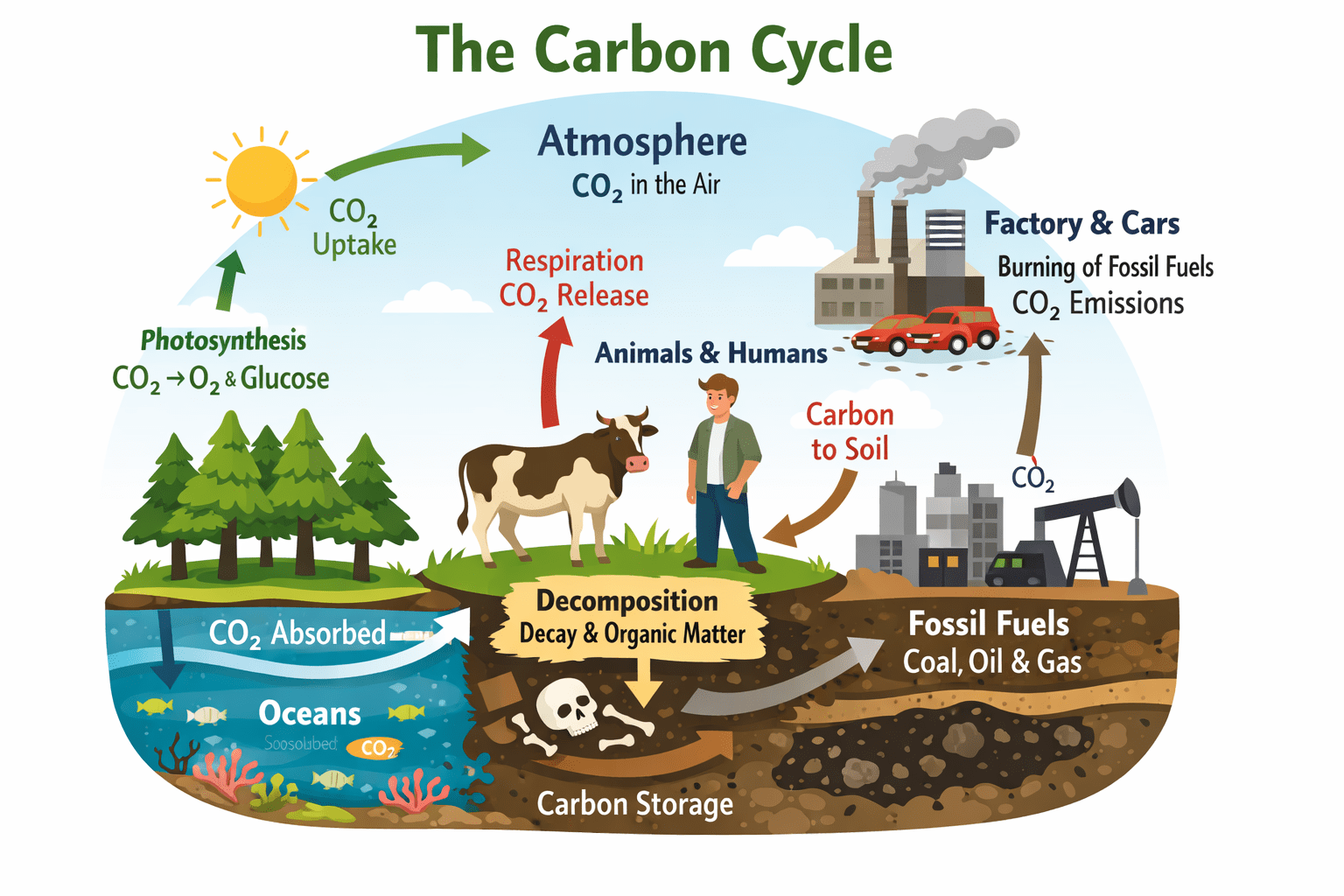

Monitoring pH During Drug Formulation

Monitoring pH during drug formulation ensures that the chemical stability, solubility, and efficacy of active pharmaceutical ingredients remain within optimal limits throughout mixing and solution preparation. pH deviations can alter drug potency, affect degradation rates, and influence product safety. Continuous or periodic pH measurement allows immediate correction before the formulation proceeds to the next production stage.

Environmental Microbial Counts During Sterile Production

Environmental microbial monitoring measures the presence and level of microorganisms in cleanrooms and production areas where sterile products are manufactured. This process ensures that airborne particles, surfaces, and personnel do not introduce contamination into the product. Regular microbial counts help verify aseptic conditions and maintain compliance with sterility standards throughout production.

Weight Variation Checks During Tablet Compression

Weight variation checks during tablet compression ensure that each tablet contains a consistent amount of active pharmaceutical ingredient and excipients. Variability in tablet weight may indicate equipment malfunction or feed inconsistency. Monitoring weight during compression allows early detection of deviations and ensures uniform dosing accuracy before batch completion.

Temperature Monitoring During Vaccine Production

Temperature monitoring during vaccine production ensures that biological materials remain within defined thermal conditions to preserve antigen stability and biological activity. Many vaccines and biologics are sensitive to heat fluctuations, which can reduce potency or cause degradation. Continuous temperature tracking during production safeguards product integrity and supports compliance with validated manufacturing parameters.

Relationship Within GMP

Both QC and IPC operate under the umbrella of Good Manufacturing Practice (GMP). GMP establishes the regulatory framework for ensuring that pharmaceutical products are consistently produced and controlled according to quality standards.

QA oversees and integrates GMP, QC, and IPC into a coherent system.

Scope of Quality Assurance Across Healthcare and Pharmaceutical Systems

QA operates across diverse healthcare and pharmaceutical domains to ensure reliability, safety, regulatory compliance, and scientific integrity. It is therefore both a regulatory obligation and a scientific necessity.

QA is applied across multiple domains:

Pharmaceutical Manufacturing

Drug formulation

QA ensures that active pharmaceutical ingredients and excipients are accurately measured, properly mixed, and consistently processed to achieve the intended therapeutic effect and stability.

Vaccine production

QA oversees antigen selection, inactivation or attenuation processes, purification steps, and sterility testing to guarantee vaccine safety, potency, and immunogenic consistency.

Injectable sterile preparations

QA monitors aseptic processing, environmental control, sterilization validation, and endotoxin testing to prevent contamination in products administered directly into the bloodstream or tissues.

Biologics

QA verifies the manufacturing consistency of complex biological products such as monoclonal antibodies and recombinant proteins through process validation and stringent quality monitoring.

Medical devices

QA ensures design validation, material safety, performance testing, and regulatory documentation compliance to confirm that devices function safely and effectively for patient use.

Hospital and Clinical Laboratories

Microbiology laboratories

QA maintains accuracy in pathogen identification, culture techniques, antimicrobial susceptibility testing, and contamination control to support correct diagnosis and treatment.

Hematology laboratories

QA validates blood count analyses, coagulation testing, and hematologic parameter measurements to ensure precise and reproducible diagnostic results.

Molecular diagnostics

QA controls nucleic acid extraction, amplification accuracy, assay validation, and contamination prevention to guarantee reliable genetic and pathogen detection results.

Histopathology services

QA supervises tissue processing, staining quality, slide interpretation consistency, and specimen handling to ensure accurate pathological diagnosis.

Public Health and Environmental Laboratories

Water quality testing

QA ensures accurate detection of chemical contaminants and microbial pathogens in water supplies through validated testing methods and calibration of analytical instruments.

Food microbiology

QA verifies detection of foodborne pathogens, contamination levels, and microbial counts to protect public health and maintain food safety standards.

Antimicrobial resistance surveillance

QA standardizes testing methods, data recording, and interpretation of resistance patterns to ensure reliable monitoring of resistance trends in populations.

Academic and Research Institutions

Validation of research data

QA ensures that experimental procedures, data collection, and statistical analyses are performed accurately and transparently to support credible scientific findings.

Reproducibility assurance

QA promotes standardized protocols, proper documentation, and methodological consistency so that research results can be independently replicated.

Biosafety compliance

QA enforces safe laboratory practices, containment procedures, and regulatory adherence to minimize biological hazards and protect researchers and the environment.

Quality Assurance in these sectors functions as both a regulatory requirement and a scientific framework that sustains integrity, safety, and operational excellence across healthcare and pharmaceutical systems.

Core Components of an Effective Quality Assurance System

An effective QA system integrates the following structural pillars:

1. Quality Management System (QMS)

A QMS is the overarching framework that documents organizational policies, processes, and responsibilities to ensure consistent delivery of products or services that meet regulatory and customer requirements. It integrates governance, operational control, monitoring, and continuous improvement into a structured system. The QMS must be documented, controlled, and periodically reviewed.

Key elements of the QMS include:

- Quality policy

- Quality objectives

- Organizational structure

- Process mapping

- Risk-based thinking

- Performance indicators

Quality policy: A quality policy is a formal statement issued by top management that defines the organization’s commitment to quality, compliance, and continuous improvement. It establishes strategic direction and communicates expectations regarding regulatory adherence, customer satisfaction, and operational excellence.

Quality objectives: Quality objectives are measurable targets derived from the quality policy that guide operational performance. They provide specific, time-bound goals that allow the organization to evaluate whether its processes and systems are achieving intended quality outcomes.

Organizational structure: Organizational structure defines roles, responsibilities, authority, and reporting relationships within the quality system. It ensures accountability by clearly assigning tasks to qualified personnel and preventing ambiguity in decision-making and quality oversight.

Process mapping: Process mapping involves documenting and visually outlining workflows to show how inputs are transformed into outputs. It helps identify process interactions, critical control points, inefficiencies, and potential risks within operational activities.

Risk-based thinking: Risk-based thinking is a proactive approach that identifies, assesses, and mitigates potential failures that could affect product or service quality. It prioritizes actions based on risk severity and likelihood to prevent deviations before they occur.

Performance indicators: Performance indicators are measurable metrics used to monitor system effectiveness and process performance. They provide data-driven insight into compliance levels, operational efficiency, defect rates, and overall quality trends for informed decision-making and continuous improvement.

2. Standard Operating Procedures (SOPs)

SOPs are controlled documents that describe step-by-step instructions for performing specific tasks. They ensure consistency, regulatory compliance, reproducibility, and operational standardization across personnel and processes. SOPs eliminate variability and ensure procedural reproducibility.

Essential features of the SOPs:

- Clear scope and purpose

- Defined responsibilities

- Version control

- Review and approval signatures

- Effective dates

Clear scope and purpose define the boundaries, objectives, applicability, and intended use of the procedure to prevent ambiguity and misuse.

Defined responsibilities specify the roles, departments, or individuals accountable for executing, supervising, reviewing, and enforcing the procedure.

Version control maintains a documented record of revisions, updates, and amendments to ensure users access the most current and approved version.

Review and approval signatures provide formal authorization by designated personnel to confirm technical accuracy, regulatory compliance, and organizational acceptance.

Effective dates indicate the official date when the procedure becomes operational, ensuring implementation aligns with approved revisions and organizational policy.

3. Personnel Training and Competency

Human error is a major source of quality failure. Human error remains one of the most significant contributors to deviations, non-conformities, and quality failures in regulated environments such as pharmaceutical manufacturing and laboratory operations. A robust quality assurance (QA) system must therefore integrate structured mechanisms to reduce variability in human performance and ensure sustained competence. Competency assessment ensures that personnel can perform tasks according to SOPs.

Therefore, QA systems to mitigate human errors must include:

- Initial training programs

- Continuing professional development

- Competency testing

- Documentation of qualifications

- Periodic re-certification

Initial Training Programs: Initial training programs ensure that personnel acquire the foundational knowledge, technical skills, and regulatory awareness required to perform assigned tasks correctly from the outset. These programs typically cover standard operating procedures, safety protocols, equipment operation, data documentation practices, and applicable regulatory requirements. Structured onboarding minimizes early-stage errors and aligns staff behavior with organizational quality standards. Effective initial training also incorporates practical demonstrations and supervised hands-on practice to reinforce theoretical instruction.

Continuing Professional Development (CPD): Continuing professional development maintains and enhances employee competence by providing ongoing education and exposure to evolving technologies, updated regulations, and improved methodologies. In dynamic fields such as pharmaceutical production and clinical diagnostics, standards and scientific knowledge frequently change. CPD programs include workshops, refresher courses, seminars, and technical updates that ensure personnel remain current and adaptable. This continuous learning culture reduces skill decay and improves overall system resilience against quality deviations.

Competency Testing: Competency testing is the formal assessment of an individual’s ability to perform assigned duties according to established procedures and performance benchmarks. It typically involves written evaluations, practical demonstrations, proficiency testing, and supervised task execution. By objectively measuring skill proficiency, organizations can identify knowledge gaps and implement targeted corrective training. Competency testing strengthens accountability and ensures that only qualified personnel execute critical quality-related tasks.

Documentation of Qualifications: Documentation of qualifications involves maintaining accurate and up-to-date records of employee education, certifications, training completion, licenses, and professional credentials. These records provide verifiable evidence that personnel meet the qualification requirements for their roles. Proper documentation supports regulatory inspections, internal audits, and traceability. It also ensures transparency in workforce capabilities and facilitates rapid verification of staff readiness for specific technical responsibilities.

Periodic Re-Certification: Periodic re-certification ensures that personnel retain their technical proficiency and remain compliant with updated standards and procedural changes over time. Skills can deteriorate without practice, and regulations or technologies may evolve. Re-certification typically involves reassessment of knowledge, practical skill evaluation, and review of updated protocols. This process reinforces continuous competence, mitigates performance drift, and maintains sustained quality assurance within the organization.

4. Equipment Qualification and Calibration

All critical equipment used in regulated environments must undergo structured qualification to ensure it operates reliably and consistently within predefined specifications. The qualification lifecycle typically includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). Each phase verifies different aspects of equipment integrity and functionality. Regular calibration schedules must be documented and traceable to certified reference standards. Uncalibrated equipment invalidates data integrity.

All critical equipment must undergo:

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

Installation Qualification (IQ): Installation Qualification verifies and documents that equipment has been installed correctly according to manufacturer specifications and approved design requirements. It confirms that utilities, connections, components, and documentation are properly configured before use. IQ ensures that the equipment delivered matches procurement specifications and is physically installed in the designated location with appropriate environmental conditions. It also checks calibration certificates, user manuals, wiring, piping connections, software installation, and safety features to confirm compliance with installation standards.

Operational Qualification (OQ): Operational Qualification demonstrates that installed equipment functions according to its operational specifications across defined operating ranges. It involves testing equipment controls, alarms, sensors, parameters, and safety mechanisms under simulated or actual operating conditions. OQ confirms that the system performs as intended when challenged with minimum, nominal, and maximum settings. It verifies process controls, response to deviations, accuracy of readings, and system stability to ensure reliable performance under expected operational conditions.

Performance Qualification (PQ): Performance Qualification confirms that the equipment consistently performs effectively under real or simulated production conditions using actual materials or representative test samples. PQ evaluates long-term stability, reproducibility, and consistency of output when the equipment is integrated into routine workflows. It ensures that the system produces products or results that meet predefined quality criteria over repeated cycles. PQ represents the final stage of validation before routine operational deployment and regulatory approval for use.

5. Process Validation

Validation demonstrates that a process consistently produces results that meet predefined specifications, regulatory requirements, and quality standards before routine implementation or continued operation. It provides documented evidence that a system, method, or process performs reliably under defined conditions and yields outputs that satisfy intended use. Validation is especially critical in sterile pharmaceutical production and microbiological testing.

Types of validation include:

- Prospective validation

- Concurrent validation

- Retrospective validation

- Re-validation after change

Prospective validation: Prospective validation is performed before a new process, product, or system is introduced into routine production to confirm that it will consistently meet quality requirements. It involves designing experiments, collecting data, and evaluating performance under controlled conditions prior to full-scale implementation.

Concurrent validation: Concurrent validation is conducted while a process is being implemented and producing actual batches or outputs. It verifies performance in real-time by collecting and analyzing data during routine production to ensure compliance with established specifications.

Retrospective validation: Retrospective validation evaluates historical production data from previously completed batches to determine whether an existing process has consistently met quality standards. It relies on documented records, batch reports, and performance trends to assess process reliability.

Re-validation after change: Re-validation after change is performed when significant modifications occur in materials, equipment, procedures, environment, or personnel that may affect process performance. It ensures that the process remains validated and continues to produce outputs that meet defined quality requirements after changes are implemented.

6. Environmental Monitoring

For sterile products such as injectables and vaccines, quality assurance must include systematic monitoring of environmental conditions to ensure controlled production areas remain free from microbial and particulate contamination that could compromise product sterility and patient safety. Environmental monitoring ensures aseptic integrity.

For sterile products (e.g., injectables, vaccines), QA must include:

- Air particulate monitoring

- Surface microbial counts

- Personnel contamination monitoring

- HEPA filter integrity testing

Air particulate monitoring: Air particulate monitoring involves continuous or periodic measurement of airborne particles to ensure that controlled cleanroom environments remain within defined contamination limits. It detects dust, microbial carriers, and other particulate matter that could compromise product sterility. This monitoring confirms that air quality consistently meets regulatory cleanroom classification standards.

Surface microbial counts: Surface microbial counts assess the level of viable microorganisms present on equipment, work surfaces, walls, and other contact areas within sterile production zones. Swab or contact plate methods are used to quantify contamination and verify the effectiveness of cleaning and disinfection procedures. This practice helps identify potential contamination sources before they affect product integrity.

Personnel contamination monitoring: Personnel contamination monitoring evaluates the microbial load on operators working in aseptic areas to prevent transfer of microorganisms to sterile products. It typically includes gown sampling, glove prints, and routine microbiological testing of staff involved in production activities. This control ensures that human intervention does not introduce contamination into critical processing environments.

HEPA filter integrity testing: HEPA (High Efficiency Particulate Air) filter integrity testing verifies that high-efficiency particulate air filters function correctly and effectively remove airborne particles from controlled environments. Methods such as aerosol challenge testing are used to detect leaks or filter damage that could compromise air filtration performance. Regular testing ensures that the filtration system maintains the required protection level for sterile manufacturing areas.

7. Documentation and Record Control

Documentation and record control form the backbone of a compliant and traceable quality system. The principle “If it is not documented, it did not happen” underscores that all critical activities, decisions, and observations must be formally recorded to ensure accountability, reproducibility, regulatory compliance, and audit readiness. QA requires structured documentation systems that capture evidence of process execution, product quality, and operational control. In documentation and record control, data integrity principles (ALCOA: Attributable, Legible, Contemporaneous, Original, Accurate) must be upheld.

For proper documentation and record control, QA requires:

- Batch manufacturing records

- Laboratory notebooks

- Deviation reports

- Audit trails

- Electronic data integrity safeguards

Batch Manufacturing Records (BMRs): Batch manufacturing records provide a complete, step-by-step documented account of how a specific production batch was manufactured and controlled. They capture raw material details, processing parameters, equipment used, in-process checks, and personnel responsible for each activity. BMRs ensure traceability from raw materials to finished product release and support investigation during deviations or recalls.

Laboratory Notebooks: Laboratory notebooks serve as primary records of experimental work, test results, calculations, and observations conducted during quality testing or research activities. They document procedures followed, reagents used, instrument readings, and unexpected findings. Properly maintained notebooks ensure reproducibility, scientific integrity, intellectual property protection, and regulatory defensibility.

Deviation Reports: Deviation reports document any departure from approved procedures, specifications, or established standards during manufacturing or testing. They describe the nature of the deviation, root cause analysis, potential product impact, and corrective actions taken. Recording deviations enables systematic investigation, risk assessment, and implementation of preventive measures to avoid recurrence.

Audit Trails: Audit trails are chronological records that track changes made to documents, data, or system entries within controlled environments. They capture who made changes, what modifications were made, when the changes occurred, and why they were necessary. Audit trails promote transparency, data traceability, accountability, and detection of unauthorized alterations in regulated systems.

Electronic Data Integrity Safeguards: Electronic data integrity safeguards are technical and procedural controls implemented to protect digital records from unauthorized access, alteration, deletion, or corruption. These safeguards include user authentication, role-based access control, data backup systems, encryption, and secure servers. They ensure compliance with data integrity principles such as ALCOA+ and maintain the reliability and authenticity of electronic quality records.

8. Internal Audits and Inspections

Internal audits evaluate compliance with:

- SOPs

- GMP standards

- Regulatory guidelines

- Institutional policies

Audit findings must trigger corrective and preventive action (CAPA) procedures.

9. Corrective and Preventive Action (CAPA)

Corrective and Preventive Action (CAPA) is a structured quality management mechanism used to identify deviations, investigate their causes, implement solutions, and prevent recurrence within regulated systems such as pharmaceutical manufacturing and laboratory operations. CAPA prevents recurrence of non-conformities.

CAPA addresses the following components:

- Root cause analysis

- Corrective measures

- Preventive measures

- Effectiveness verification

Root Cause Analysis – A systematic investigation process used to determine the fundamental underlying factors that led to a deviation, non-conformity, or failure rather than focusing only on superficial symptoms.

Corrective Measures – Targeted actions implemented to eliminate the detected non-conformity and fix the immediate problem to restore compliance and operational stability.

Preventive Measures – Proactive strategies introduced to eliminate potential causes of similar future deviations and reduce the likelihood of recurrence across related processes.

Effectiveness Verification – A follow-up evaluation conducted after implementing corrective and preventive actions to confirm that the measures successfully resolved the issue and prevented its repetition.

Quality Assurance in Pharmaceutical Products

Pharmaceutical products such as oral tablets, sterile injectables, vaccines, and biologics are designed for direct or systemic administration into the human body. Because they interact with physiological systems and can exert profound therapeutic or adverse effects, their quality attributes must be rigorously controlled through structured quality assurance systems. Therefore, the quality profile of these products must satisfy three critical parameters:

- Safety

- Efficacy

- purity

Safety: Safety refers to the assurance that a pharmaceutical product does not cause unacceptable adverse effects when used under specified conditions. It encompasses toxicological evaluation, impurity control, sterility assurance, and risk mitigation throughout development and manufacturing. Quality assurance systems evaluate raw materials, excipients, active pharmaceutical ingredients, and finished products to detect contaminants such as microbial agents, endotoxins, heavy metals, or toxic residual solvents. Safety testing also includes pharmacovigilance monitoring after-market release to identify rare or delayed adverse reactions. By implementing validated processes, environmental controls, and rigorous testing protocols, manufacturers minimize patient exposure to harmful substances and reduce the probability of product-related harm.

Efficacy: Efficacy describes the ability of a pharmaceutical product to produce the intended therapeutic effect at the prescribed dose and under recommended conditions of use. Quality assurance ensures that the active ingredient is present at the correct concentration, maintains chemical stability, and remains bioavailable throughout its shelf life. Process validation, formulation optimization, and stability studies confirm that the product consistently delivers predictable pharmacological activity. Analytical testing verifies potency, dissolution rate, and release characteristics to ensure therapeutic consistency between batches. Without efficacy assurance, even a safe product may fail to achieve clinical outcomes, undermining treatment success and public confidence in healthcare interventions.

Purity: Purity indicates that the pharmaceutical product contains the correct active ingredient without unacceptable levels of impurities, contaminants, degradation products, or extraneous materials. Quality assurance systems establish strict specifications for raw materials and manufacturing environments to prevent cross-contamination and chemical degradation. Purity testing includes chromatographic analysis, spectroscopic characterization, microbial limit testing, and detection of residual solvents or manufacturing by-products. Maintaining purity requires validated cleaning procedures, controlled production environments, and proper storage conditions. High purity ensures product consistency, reduces the risk of unexpected toxic effects, and supports regulatory compliance with pharmacopeial standards and good manufacturing practice requirements.

Sterility Assurance

Sterile pharmaceutical products must be free from:

- Viable microorganisms

- Pyrogens (e.g., endotoxins)

- Particulate matter

QA personnel ensure compliance with sterility standards through:

- Sterility testing

- Endotoxin testing

- Media fill validation

- Cleanroom validation

Batch Release Certification

No pharmaceutical product is released into the market without QA approval. QA functions independently of production to avoid conflict of interest.

The QA unit:

- Reviews batch records

- Confirms compliance with specifications

- Ensures deviation resolution

- Certifies release

Stability Studies

Stability studies are systematic investigations conducted to determine how the quality attributes of a pharmaceutical product change over time under defined environmental conditions. These studies ensure that the product maintains its identity, strength, purity, and safety throughout its intended shelf life. Within a quality assurance framework, stability studies generate scientific evidence that supports product expiration dating, storage conditions, and packaging integrity. QA ensures that products remain within specification over time under defined storage conditions.

Stability programs include:

- Accelerated stability testing

- Long-term stability testing

- Ongoing stability monitoring

These data determine product shelf-life.

Accelerated Stability Testing: Accelerated stability testing involves storing pharmaceutical products under elevated temperature and humidity conditions to speed up the degradation process and predict long-term stability behavior. This approach provides early indications of potential chemical breakdown, physical instability, or microbiological changes within a shortened timeframe. Data obtained from accelerated studies are used to estimate shelf life and identify critical degradation pathways.

Accelerated testing is particularly useful during product development and formulation optimization because it allows rapid assessment of stability performance. Regulatory authorities often require this type of data to support initial product registration and market authorization. However, the conditions used in accelerated testing must be scientifically justified and aligned with recognized guidelines to ensure reliable extrapolation of results.

Long-Term Stability Testing: Long-term stability testing evaluates pharmaceutical products under recommended storage conditions for an extended period that typically matches or exceeds the intended shelf life. This testing monitors critical quality attributes such as potency, appearance, pH, dissolution profile, sterility, and impurity levels over time.

Long-term studies provide direct evidence that the product remains stable under real-world storage conditions. Unlike accelerated testing, which predicts behavior, long-term testing confirms actual performance over time. Regulatory agencies require continuous long-term stability data for product approval and post-approval compliance, ensuring that shelf-life claims are scientifically validated.

Ongoing Stability Monitoring: Ongoing stability monitoring is a continuous quality assurance activity conducted after product commercialization to confirm that stability characteristics remain consistent during routine manufacturing and distribution. It involves periodic testing of marketed batches to detect any unexpected trends or deviations from established specifications.

This monitoring system helps identify manufacturing variability, raw material changes, equipment issues, or packaging failures that may affect product quality. Data from ongoing stability programs support continuous improvement and regulatory compliance by ensuring that previously validated stability conclusions remain valid throughout the product lifecycle.

Quality Assurance in Clinical Microbiology Laboratories

In microbiology laboratories, QA ensures accurate detection of pathogens and antimicrobial resistance patterns.

Critical QA areas include:

- Media sterility testing

- Quality control strains

- Antimicrobial susceptibility testing validation

- External quality assessment schemes

- Biosafety compliance

Given the global burden of antimicrobial resistance for example, inaccurate laboratory reporting can misguide treatment and exacerbate resistance trends.

Regulatory and Compliance Framework

QA systems operate under national and international regulations, including:

- GMP guidelines

- ISO standards (e.g., ISO 15189 for medical laboratories)

- National drug regulatory authorities

- Pharmacopoeial standards

Regulatory inspections evaluate:

- Documentation

- Training records

- Equipment logs

- Deviation handling

- Complaint management

Non-compliance may result in product recalls, fines, or license suspension.

Risk Management in Quality Assurance

Modern QA incorporates risk-based approaches, such as:

- Failure Mode and Effects Analysis (FMEA)

- Hazard Analysis and Critical Control Points (HACCP)

- Risk matrices

Risk assessment identifies potential failure points and prioritizes mitigation strategies.

Continuous Quality Improvement (CQI)

QA is not static; thus, continues improvement of the process is very essential. Quality maturity evolves over time through iterative refinement.

Continuous improvement involves:

- Trend analysis

- Performance benchmarking

- Process optimization

- Lean manufacturing principles

- Six Sigma methodologies

Consequences of Poor Quality Assurance

Failure of QA systems may lead to:

- Contaminated pharmaceutical products

- Incorrect laboratory diagnoses

- Therapeutic failure

- Drug recalls

- Litigation

- Public health crises

Ethical and Public Health Dimensions

QA extends beyond regulatory compliance. It is fundamentally an ethical obligation. Therefore, QA aligns with principles of bioethics: beneficence, non-maleficence, and justice.

Inadequate QA in pharmaceuticals or diagnostic laboratories can:

- Compromise patient safety

- Distort epidemiological data

- Undermine antimicrobial stewardship programs

- Exacerbate global health inequities

Steps to Take in Implementing a Practical QA Framework

To operationalize QA effectively:

Step 1: Establish a Quality Policy

Define commitment to quality and compliance.

Step 2: Develop a QMS Structure

Document procedures, define responsibilities.

Step 3: Conduct Risk Assessment

Identify critical control points.

Step 4: Develop SOPs

Standardize all procedures.

Step 5: Train Personnel

Ensure competency before task assignment.

Step 6: Validate Processes

Confirm reproducibility and reliability.

Step 7: Implement Monitoring Systems

Track performance metrics.

Step 8: Audit Regularly

Evaluate compliance gaps.

Step 9: Execute CAPA

Address deviations systematically.

Step 10: Review and Improve

Conduct periodic management reviews.

References

Arora D.R (2004). Quality assurance in microbiology. Indian J Med Microbiol, 22:81-86.

Block S.S (2001). Disinfection, sterilization and preservation. 5th edition. Lippincott Williams & Wilkins, Philadelphia and London.

Cars O and Nordberg P (2005). Antibiotic resistance: The faceless threat. International Journal of Risk & Safety in Medicine, 17 (3/4): 103-110.

Cowan M.M (1999). Plant products as antimicrobial agents. Clinical Microbiology Reviews., 564-582.

Denyer S.P., Hodges N.A and Gorman S.P (2004). Pharmaceutical Microbiology. 7th ed. Blackwell Publishing Company, USA.

Finch R.G, Greenwood D, Norrby R and Whitley R (2002). Antibiotic and chemotherapy, 8th edition. Churchill Livingstone, London and Edinburg.

Joslyn, L. J. (2000). Sterilization by Heat. In S. S. Block (Ed.), Disinfection, Sterilization, and Preservation (5th ed., pp. 695-728). Philadelphia, USA: Lippincott Williams and Wilkins.

Nally J.D (Ed.) (2007). Good manufacturing practices for pharmaceuticals. Sixth edition. Informa Healthcare USA, Inc, New York.

Discover more from Microbiology Class

Subscribe to get the latest posts sent to your email.